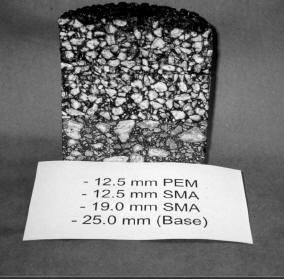

When the crew arrived in the morning the mix was there. “When you have something like that you just want to get in and get it done. “We were just busy and we wanted to get it behind us,” said Goodhue when asked about the accelerated effort. Des Moines Asphalt and Paving met the challenge by using a fleet of over 20 trucks to haul and place more than 5,000 tons daily. The project called for 127,000 tons of special backfill, 49,000 tons of granular shoulder rock, 125,000 tons of hot-mix asphalt (HMA) base, 23,000 tons of HMA binder course and 22,000 tons of HMA surface course.

#Higher type mix base widening asphalt iowa dot full#

Once the project shifted into full gear the transportation of materials was immense. Existing portland cement concrete (PCC) pavement was removed and crushed to meet gradation for the granular sub-base, which was 6 in. The extra precipitation temporarily delayed the project, which started in late April with trimming of the grade and the creation of a special backfill for the reconstruction of 11/2 miles of road near the new interchange located in the town of Granger. The year 1997 wasn’t a particularly good one for dirt contractors in Iowa, not after a wet season. “The weather was good and we just ran pretty hard,” said Robert Goodhue, vice president of operations at Des Moines Asphalt & Paving. Building on its success, Des Moines Asphalt & Paving is going to resurface the two older lanes this year. There were no incentives for finishing early, but the company did receive $110,000 in incentives for smoothness. The expansion, which took about eight months and $8.1 million to finish, also included the reconstruction of nearly two miles of the existing highway at two separate locations, the relocation of a curve and the building of an interchange. Through competitive bidding with four other contractors, Des Moines Asphalt & Paving won the job behind a cost estimate of $8 million and a completion date set for 1998. “I figured the award he was talking about was at the local level, I had no idea it would lead to this. In fact, we’re here to win an award for the project,’” recalled Jimerson. “Jim came to me and told me, ‘We’re here to do a good job. Gauger also served as project manager for the contractor.

The plan called for the 12-mile strip to be converted into a four-lane divided highway, and right from the beginning Robert Jimerson, the project manager for the Iowa DOT (IDOT) on the job, was anxious to see the construction unfold after talking with Jim Gauger, vice president of sales for Des Moines Asphalt & Paving. The recent surge explains the expansion to Iowa 141, which handles 8,100 cars and trucks daily, between Des Moines and Perry.

Volume has gone up more than 63% this decade.

The National Center for Asphalt Technology was the first to conduct checks, then an independent pavement consulting firm ran tests for smoothness before a final inspection was conducted by an independent pavement engineer.ĭallas County is one of the fastest growing counties in the state of Iowa, and with growth comes an increase in traffic. The pavement goes through three rounds of judging. The Hayes award is given each year by the National Asphalt Pavement Association (NAPA) to the HMA pavement judged the highest quality in the nation. The goal was accomplished in a big and unique way during the construction of two new lanes of highway on Iowa 141 in Dallas County in 1997, as over 346,000 tons of material was produced and placed during the project, which finished a year ahead of schedule and earned the company the Sheldon G. 1 objective of highway construction: Keep the masses moving. By: Bill WilsonDes Moines Asphalt & Paving Co.

0 kommentar(er)

0 kommentar(er)